Compressed Air Dryer Rental From Compressor Now

We Partner with SPX Flow’s Hankison to:

Provide Air Treatment solutions designed and constructed to make Transportation, Installation and Operation Quick, Safe and Reliable.

Provide the largest fleet of Pre-Packaged Air Treatment systems available for immediate shipment throughout North America

Wherever and Whenever that may be! Depend on Hankison Rental the next time you need clean, dry air for supplemental or temporary emergency service requirements.

24/7 Service Support

Product Training

Easy to Operate

Largest Rental Fleet

Table of Contents

Desiccant Dryers

Eliminate troublesome liquid water from downstream air lines and equipment. For Dew Points of -40F and -100F

FEATURES

- Mounted particulate and oil removal prefilters c/w automatic condensate drains and a one micron afterfilter – no field installation of filters required

- Heavy duty frame with lifting lugs and fork lift channels for easy handling

- NEMA 4, 115/1/60 electrics – suitable for outdoor operation (all pneumatic units available)

- Units can be field adjusted for -40°F or -100°F pressure dew point

- Full instrumentation package provides ready indication of system malfunction

- High pressure models available

EASY TO USE

- Mounted on sled type skid with lifting lugs and forklift channels

- Prepiped with convenient in/out connections

- Automatic condensate drains

- Gauges on filters indicate need for element replacement

- Dryer control panel includes alarms and built-in diagnostic capabilities

RDH260

| INLET FLOW (SCFM1) | 260 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 223 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 220 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2″ NPT |

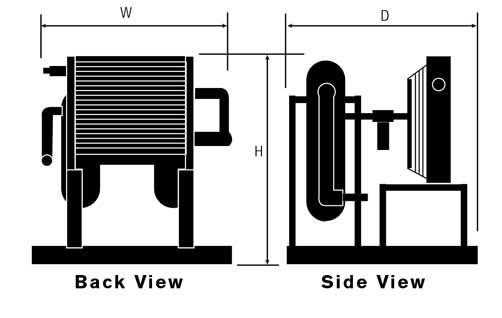

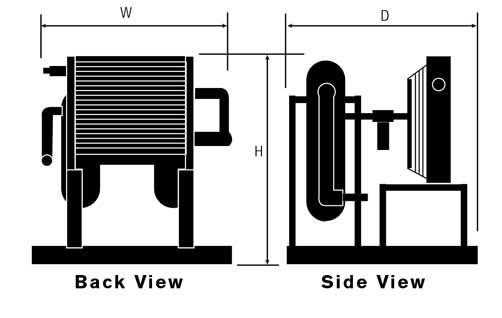

| DIMENSIONS (HxWxD) | 90x42x47 |

| WEIGHT (LBS) | 1350 |

1 Flow shown is based on inlet compressed air at 100 psi and 100°F

RDH370

| INLET FLOW (SCFM1) | 370 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 317 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 312 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2″ NPT |

| DIMENSIONS (HxWxD) | 90x42x60 |

| WEIGHT (LBS) | 1650 |

RDH450

| INLET FLOW (SCFM1) | 450 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 385 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 380 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2″ NPT |

| DIMENSIONS (HxWxD) | 92x42x60 |

| WEIGHT (LBS) | 1800 |

RDH590

| INLET FLOW (SCFM1) | 590 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 505 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 498 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2″ NPT |

| DIMENSIONS (HxWxD) | 95x50x70 |

| WEIGHT (LBS) | 2860 |

1 Flow shown is based on inlet compressed air at 100 psi and 100°F

RDH750

| INLET FLOW (SCFM1) | 750 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 642 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 634 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2 1/2″ NPT |

| DIMENSIONS (HxWxD) | 97x58x72 |

| WEIGHT (LBS) | 3450 |

RDH930G

| INLET FLOW (SCFM1) | 930 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 796 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 786 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2 1/2″ NPT |

| DIMENSIONS (HxWxD) | 80x76x73 |

| WEIGHT (LBS) | 3500 |

RDH1550G

| INLET FLOW (SCFM1) | 1550 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 1327 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 1309 |

| WORKING PRESSURE (PSI) | 250 |

| MAX IN/OUT CONNECTIONS (IN) | 3″ Boss |

| DIMENSIONS (HxWxD) | 79x78x83 |

| WEIGHT (LBS) | 5500 |

RDH2100G

| INLET FLOW (SCFM1) | 2100 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 1797 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 1774 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 3″ Boss |

| DIMENSIONS (HxWxD) | 80x80x73 |

| WEIGHT (LBS) | 5750 |

RDH3000G

| INLET FLOW (SCFM1) | 3000 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 2567 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 2534 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 2″ x 3″ Boss |

| DIMENSIONS (HxWxD) | 81x91x115 |

| WEIGHT (LBS) | 9200 |

RDH5400G

| INLET FLOW (SCFM1) | 5400 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 4620 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 4561 |

| WORKING PRESSURE (PSI) | 150 |

| MAX IN/OUT CONNECTIONS (IN) | 4″ x 3″ Boss |

| DIMENSIONS (HxWxD) | 81x91x153 |

| WEIGHT (LBS) | 14800 |

HIGH PRESSURE @ 350 PSI

RDHHP495

| INLET FLOW (SCFM1) | 900 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 828 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 818 |

| WORKING PRESSURE (PSI) | 365 |

| MAX IN/OUT CONNECTIONS (IN) | 3″ NPT |

| DIMENSIONS (HxWxD) | 94x78x96 |

| WEIGHT (LBS) | 3800 |

RDHHP715

| INLET FLOW (SCFM1) | 1300 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 1196 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 1186 |

| WORKING PRESSURE (PSI) | 365 |

| MAX IN/OUT CONNECTIONS (IN) | 3″ NPT |

| DIMENSIONS (HxWxD) | 96x78x96 |

| WEIGHT (LBS) | 4000 |

RDHHP1550G

| INLET FLOW (SCFM1) | 2800 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 2576 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 2550 |

| WORKING PRESSURE (PSI) | 365 |

| MAX IN/OUT CONNECTIONS (IN) | 3″ Boss |

| DIMENSIONS (HxWxD) | 79x78x83 |

| WEIGHT (LBS) | 6200 |

RDHHP5200G

| INLET FLOW (SCFM1) | 9300 |

| FLOW OUTLET @ -40°F P.D.P (SCFM1) | 8530 |

| FLOW OUTLET @ -100°F P.D.P (SCFM1) | 8400 |

| WORKING PRESSURE (PSI) | 365 |

| MAX IN/OUT CONNECTIONS (IN) | 4″ x 3″ Boss |

| DIMENSIONS (HxWxD) | 81x91x153 |

| WEIGHT (LBS) | 19000 |

Aftercooler / Dryer / Filter Package

FEATURES

Aftercooler with air driven fan motor

- Lowers temperature of air leaving the compressor to within 7.5°F of ambient temperature

- Eliminates 80% of water Prefilter 1 – Separator/filter

- Removes bulk liquids

- Prefilters the air for finer filtration

Prefilter 2 – High efficiency coalescing type oil removal filter

- Removes fine oil droplets (aerosols) and solid particles 0.01 microns and larger

- Oil content after filtration: 0.008 ppm w/w

Pressure-swing (heatless) regenerative desiccant dryer

- Produces extra dry air (-40°F or -100°F pressure dew point)

- Efficient design minimizes purge air requirements

Afterfilter – 1 micron particulate filter

- Removes desiccant fines

- In-depth media allows long element life

| RDH260GAC | RDH450GAC | RDH750GAC | RDH930GAC | RDH1550AC | RDH1550GAC | RDHHP715AC | RDHHP1550AC | |

| CAPACITY @ 100 PSI (SCFM) | 185 to 260 | 260 to 500 | 600 to 800 | 800 to 1,000 | 1,000 to 1,600 | 1,000 to 1,600 | 1,300 | 2,800 |

| WORKING PRESSURE (PSI) | 250 | 250 | 150 | 150 | 150 | 250 | 350 | 350 |

| DIMENSIONS HxWxD (IN) | 82x50x69 | 82x50x69 | 80x75x71 | 80x75x71 | 97x73x81 | 87x78x83 | 96x78x96 | 87x78x83 |

| WEIGHT (LBS) | 1,500 | 2,200 | 3,600 | 3,800 | 6,000 | 6,000 | 5,000 | 7,000 |

Aftercooler / Separator

Reduce the temperature of hot compressed air leaving the compressor to safe, usable levels

FEATURES

Reduce compressed air temperatures to within 5°F to 20°F of ambient temperature.

- Makes air safe, usable, and capable of further filtering and drying

- Eliminates up to 70% of water

Aftercooler, separator, and automatic condensate drain piped and skid mounted. - Maximum working pressures to 350 psi available.

Air driven fans:

- Includes air motor, regulator, lubricator, and relief valve

| AACA-450 | AACA-1000 | AACA-1600 | AACA-2500 | AACA-3000 | AACA-3500 | |

| AIR MOTOR USEAGE (SCFM) | 10 | 20 | 70 | 80 | 120 | 120 |

| IN/OUT CONNECTIONS (NPT) | 2″ | 2″ | 3″ | 4″ | 4″ | 4″ |

| DIMENSIONS (HxWxD) (IN) | 46x48x60 | 46x48x60 | 73x48x72 | 66x48x90 | 73x60x108 | 73x60x108 |

| SHIPPING WEIGHT (LBS) | 400 | 600 | 800 | 1000 | 1200 | 1400 |

Aftercooler / Separator / Filter

FEATURES

- Lowers temperature of air leaving the compressor to within 10°F to 15°F of ambient temperature

- Eliminates 75% of water Separator/filter

- Two stage filtration

- First stage removes bulk liquids

- Second stage fiber captures solid and liquid particles to 3 micron

EASY TO USE

- Mounted on rental skid

- Prepiped with convenient in/out connections

- No power required

- Automatic condensate drains

- Gauges on filters indicate need for element replacement

| MODEL | CAPACITY (SCFM) | DIMENSIONS HxWxD (IN) | WEIGHT (LBS) |

| AFC450 | 450 | 53x46x36 | 675 |

| AFC750 | 750 | 68x48x60 | 675 |

| AFC1000 | 1000 | 73x48x72 | 950 |

| AFC1600 | 1600 | 73x48x72 | 1000 |

Aftercooler / Filter Package

Obtain Oil Free Air with Lubricated Compressors

Aftercooler with air driven fan motor

- Lowers temperature of air leaving the compressor to within 10°F to 15°F of ambient temperature

- Eliminates 80% of water

Separator/filter

- Removes bulk liquids

- Prefilters the air for finer filtration

- Large in depth bed eliminates heavy particulate load

- Gauges on filters indicate need for service

High efficiency oil removal filter

- Removes oil aerosols 0.01 micron and larger

- Remaining oil content: 0.008 ppm w/w

| MODEL | CAPACITY (SCFM) | DIMENSIONS HxWxD (IN) | WEIGHT (LBS) |

| ACFS450 | 450 | 53x46x36 | 675 |

| ACFS750 | 750 | 68x48x60 | 675 |

| ACFS1000 | 1000 | 73x48x72 | 950 |

| AFC1600ACFS1600 | 1600 | 73x48x72 | 1000 |

Filter Packages

Package 1: For liquid oil removal

- Air line filter and 0.01 micron coalescing filter

- Removes oil aerosols for virtually oil free air (remaining oil is in a vapor state)

- Air Line filter protects high efficiency filter from liquid overloading and solid particulate contamination

- Patented design maintains high oil removal efficiency for the life of the cartridge

- Removes all solid particles 0.01 microns and larger

Typical Applications

Use with oil-lubricated compressors to produce oil free air for: spray painting, powder coating, blow molding, pneumatic instrumentation, fluid logic, air bearings, pneumatic conveying, food and drug packaging, and electronics manufacturing.

Package 2: For oil vapor removal

- 0.01 micron coalescing filter and activated carbon type oil vapor removal filter

- Removes oil vapor and other hydrocarbons normally absorbable by activated carbon (produces vapor concentrations of less than 0.01 ppm w/w)

- Coalescing filter protects carbon bed from liquid contamination

- Final stage of media removes all solid particles 0.01 microns and larger

Typical Applications

Food and drug industries where compressed air contacts products, for deodorizing compressed air exhausted into confined worker environments and Conditioning gas samples ahead of analytical instruments.

CREATE YOUR OWN PACKAGE CHOOSE FROM THESE FILTERS:

Separator/filter

- Removes solid particles, water droplets, and oil aerosols three microns (mean diameter) and larger

- Protects downstream equipment from damage or malfunction

- Designed for use at locations where large liquid loads are present (downstream of aftercoolers, etc.)

Air line filter

- Removes solid particles, water droplets and oil aerosols one micron (mean diameter) and larger

- Protects downstream equipment from damage or malfunction

Coalescing type oil removal filter

- Removes liquid aerosols (specifically oil) 0.01 microns and larger

- Protects downstream instruments,

equipment, products, and processes

from oil aerosol contamination

Oil vapor removal filter

- Removes gaseous oil and various other hydrocarbon vapors

- Removes offensive odors; prevents contamination of products and processes

| MODEL | CAPACITY (SCFM) | IN/OUT CONNECTIONS (PSI) | DIMENSIONS HxWxD (IN) | WEIGHT (LBS) |

| FS375 | 375 | 3″ NPT | 44x19x24 | 125 |

| FS700 | 700 | 3″ NPT | 66x48x68 | 275 |

| FS1600 | 1600 | 3″ NPT | 66x48x90 | 400 |

The Industrial Now Group Offers A Compete Catalog For Your Facilities.